Certification

In 1998 the quality management system (QMS) of the company was ISO 9002-94 certified by the Dutch company TNO Certification. In July 2001 the quality management system of the company was ISO 9001:2000, and in May 2009 the quality management system of the company was ISO 9001:2008 certified by the Dutch company TNO Certification.

Since December 2011 at the plant it has been implemented the quality management system in accordance with the requirements of technical specification ISO/TS 16949:2009 and in April 2013 for the first time the company has received the certificate of requirements of the conformity of the technical specification ISO/TS 16949:2009 of QMS and has proved the certificate of conformity of the requirements ISO 9001:2008.

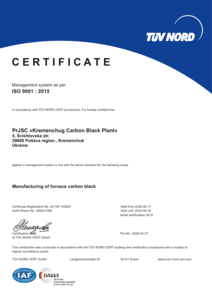

Since April 2014 the company «TÜV NORD CERT» is the certification body of KCBP.

In March 2017 the company “TUV NORD CERT” has conducted the re-certification audit QMS of LLC “KCBP”. The certificate of conformity of the QMS to the requirements of the technical specification ISO/TS 16949: 2009 was confirmed and the transition to the international standard ISO 9001:2015 was successfully completed.

In February and March 2018 the company “TUV NORD CERT” has conducted the transfer audit of QMS from ISO/TS 16949:2009 to international standard IATF 16949:2016, and corresponding surveillance audit of MS ISO 9001:2015.

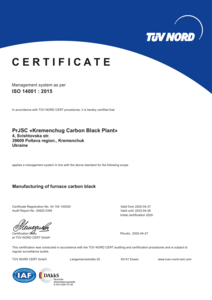

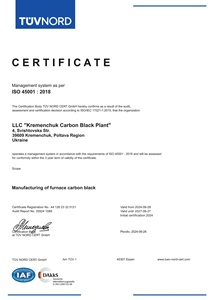

In March 2020, “TUV NORD CERT” conducted a certification audit of IMS of KCBP for compliance with the requirements of ISO 14001: 2015 and re-certification and surveillance audits of MS ISO 9001: 2015, IATF 16949: 2016.

International standards offer the application of the process approach during development, implementation and increasing of efficiency of integrated management system, with the purpose of customer satisfaction through implementation of its requirements.

The result of the implementation and functioning of the integrated management system of Limited Liability Company «Kremenchuk Carbon Black Plant» is:

For the Organization:

- improvement of internal processes for continuous improvement of business;

- fulfillment of the requirements and expectations of employees, suppliers, owners and society;

- improved functioning of the personnel;

- increased efficiency of the enterprise;

- a wider coverage of the market;

- improvement of the image and reputation.

For Customers:

- satisfaction of all special and specific requirements;

- stable product quality;

- stable deliveries on time;

- competitive cost of carbon black;

- priority of solving environmental problems;

- ISO 14001 certificate;

- corporate social responsibility of activity;

- Regulation (EU) No 1907/2006 (“REACH”).

For Society:

- involvement in the social life of the city;

- absence of harmful emissions;

- informing about the activities of the company;

- participation in environmental programs of the city;

- prevention of negative anthropogenic impact on nature in the process of production, consumption and disposal of products;

- help to the city.

For Suppliers:

- loyal business;

- timely payment;

- stability of procurement.

For Government Bodies:

- stable tax deduction;

- compliance with the requirements of Ukrainian legislation;

- assistance to the community.

At LLC «KCBP» are developed and successfully applied modern engineering methods of IMS, according to the requirements of implemented international standards:

- Contingency plan;

- Advanced product quality planning (APQP). Control plan ;

- Failure mode and effects analysis (FMEA process);

- Statistical process control (SPC) during carbon black production;

- Measurement system analysis (MSA) during carbon black production;

- Product part approval process (PPAP);

- Risk-oriented management;

- Ecological management.

At the company the Management Representative provides overall management, review and analysis of the IMS, and he is responsible for the implementation and functioning of the IMS in accordance with international standard ISO 9001:2015. As well, the Management Representative is assigned the functions of the Product Safety Representative.

Responsibility for the implementation and operation of the IMS in accordance with the international standard ISO 14001: 2015 is assigned to the Environmental Management Representative.

The company management has appointed a Consumer Representative, who is responsible for accounting and performance of customer requirements, and also this person monitors the implementation of corrective actions.

All employees of Limited Liability Company «Kremenchuk Carbon Black Plant» have the authority and responsibility for specific tasks, allowing them to take part in quality management.

Carrying out of all production processes, from incoming inspection of raw materials to shipment of finished products, is the part of the IMS, which is an important element of modern methods of controlling production processes and finished products.

The aim of the company is to improve processes in order to achieve maximum customer, staff, shareholders and society satisfaction.

Each lot of carbon black is subject to the control according to ASTM test methods the special customer requirements.

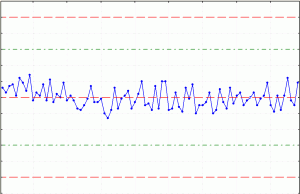

Ensuring of uniformity of manufactured product quality is the implementation of developed measures and improvement that allow narrowing the limits of quality values deviations from the recommended by standard documentation.

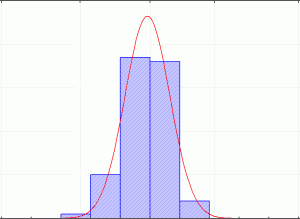

Basic statistical concepts, such as variation, control (stability), process capability and over-adjustment shall be understood and used by the enterprise.Basic statistical methods, used by the enterprise for each process, are defined in the course of advanced product quality planning (APQP) and are included in the control plan.Statistical data of products quality values are sent to the customer upon request.One of the important criteria for the customer is the consistent quality of carbon black from batch to batch, so its homogeneity and reproducibility. Therefore, the company has implemented a statistical process control, based on the requirements of SPC.

The company determined key characteristics of carbon black, namely Iodine Adsorption Number, Oil Absorption Number, Sieve residue №325. These quality values of carbon black are used in the calculation of the index of suitability Pp / Ppk with the purpose of continuous improving of the process of carbon black production, for full customer satisfaction of the products quality, produced by LLC “KCBP”.

The plant has been conducting measuring systems analysis (MSA) to control the quality values of carbon black (key characteristics) for incoming inspection of test equipment, during the process of carbon black testing.

It has been conducting failure mode and effects analysis (FMEA process). This is a team work, whose actions are aimed at identifying and quantitative evaluation of potential product defects, discrepancies of production process, as well as their causes and consequences in order to eliminate or reduce the failure probability.

In the supply of carbon black and purchased material resources for its production has been conducting the product approval with customers in accordance with the PPAP method.

For the process of continuous improvement monthly company departments develop the improvements, which are reviewed and approved by the plant Day Quality.

In each company department a quality representative is designated who organizes the functioning of quality circles, brings the quality tasks to the staff, makes a plan of improving. Monthly quality representatives provide to Management Representative the reports of fulfillment of the tasks of improvements.

At Limited Liability Company «Kremenchuk Carbon Black Plant» the improving production process is focused on managing and reducing of the variations in product characteristics and parameters of the manufacturing process.